Precision Spur / Helical Gear Rack

Pinion Gear Rack

We offer customization options for racks to serve as accessories for machines and CNC tools across various applications.

Sixstar produce, grind and fabricate precision spur gear racks and helical gear racks of all kinds. We can customize racks as accessory to machines and CNC tools of different applications.

We welcome custom drawings for our evaluation, and our experienced team will be glad to assist you. Whether you need standard or tailored solutions, Sixstar is dedicated to meeting your specific requirements with high-quality products and exceptional service.

Capability of Sixstar Gear Rack:- Grinding precision of JIS grade 2 (DIN 6, AGMA 12)

- Rack teeth rollers are capable of M2-M14 process modulus and can fabricate one single workpiece up to 2 meters without joint.

Features

- Various materials available.

- Rectangular or round shape.

- With or without heat treatment.

- Customization is available.

- Manufactured in many lengths and heights.

- Ends capable to join with one another.

Specification

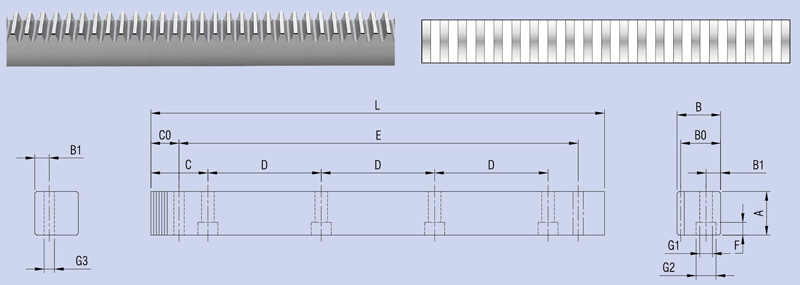

Spur (Straight) Gear Rack- Spur gear racks have the teeth perpendicular to rack length.

- Converts rotary motion into linear motion to carry heavy loads.

Dimension: mm

| Module | L | Tooth No. | A | B | B0 | C | D | Hole No. | B1 | G1 | G2 | F | C0 | E | G3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.5 | 499.51 | 106 | 17 | 17 | 15.5 | 62.44 | 124.88 | 4 | 8 | 6 | 9.5 | 7 | 29.0 | 441.5 | 5.7 |

| 1.5 | 999.03 | 212 | 17 | 17 | 15.5 | 62.44 | 124.88 | 8 | 8 | 6 | 9.5 | 7 | 29.0 | 941.0 | 5.7 |

| 2 | 502.64 | 80 | 24 | 24 | 22 | 62.83 | 125.66 | 4 | 8 | 7 | 11 | 7 | 31.3 | 440.1 | 5.7 |

| 2 | 1005.28 | 160 | 24 | 24 | 22 | 62.83 | 125.66 | 8 | 8 | 7 | 11 | 7 | 31.3 | 942.7 | 5.7 |

| 3 | 508.95 | 54 | 29 | 29 | 26 | 63.62 | 127.23 | 4 | 9 | 10 | 15 | 9 | 34.4 | 440.1 | 7.7 |

| 3 | 1017.9 | 108 | 29 | 29 | 26 | 63.62 | 127.23 | 8 | 9 | 10 | 15 | 9 | 34.4 | 949.1 | 7.7 |

| 4 | 502.64 | 40 | 39 | 39 | 35 | 62.83 | 125.66 | 4 | 12 | 10 | 15 | 9 | 37.5 | 427.7 | 7.7 |

| 4 | 1005.28 | 80 | 39 | 39 | 35 | 62.83 | 125.66 | 8 | 12 | 10 | 15 | 9 | 37.5 | 930.3 | 7.7 |

| 5 | 502.65 | 32 | 49 | 39 | 34 | 62.83 | 125.66 | 4 | 12 | 14 | 20 | 13 | 30.1 | 442.4 | 11.7 |

| 5 | 1005.31 | 64 | 49 | 39 | 34 | 62.83 | 125.66 | 8 | 12 | 14 | 20 | 13 | 30.1 | 945 | 11.7 |

| 6 | 508.95 | 27 | 59 | 49 | 43 | 63.62 | 127.23 | 4 | 16 | 18 | 26 | 17 | 31.4 | 446.1 | 15.7 |

| 6 | 1017.9 | 54 | 59 | 49 | 43 | 63.62 | 127.23 | 8 | 16 | 18 | 26 | 17 | 31.4 | 955.0 | 15.7 |

| 8 | 502.64 | 20 | 79 | 79 | 71 | 62.83 | 125.66 | 4 | 25 | 22 | 33 | 21 | 26.6 | 449.5 | 19.7 |

| 8 | 1005.28 | 40 | 79 | 79 | 71 | 62.83 | 125.66 | 8 | 25 | 22 | 33 | 21 | 26.6 | 952 | 19.7 |

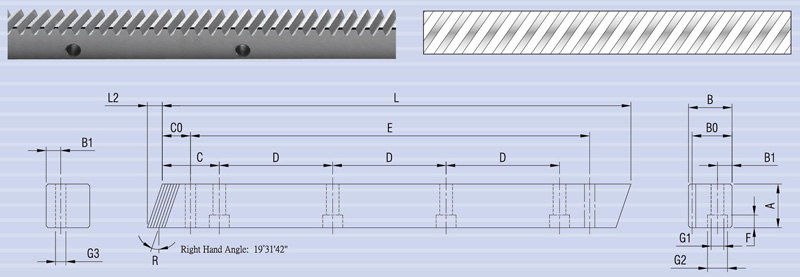

Helical (Skew) Gear Rack

- Runs quieter than the spur gear rack, especially at high speeds.

- Helical rack & pinion has a higher contact ratio (the number of effective teeth engaged) than straight, which increases the load carrying capacity.

Dimension: mm

Dimension: mm| Module | L | L2 | Tooth No. | A | B | B0 | C | D | Hole No. | B1 | G1 | G2 | F | C0 | E | G3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.5 | 500.00 | 6 | 100 | 17 | 17 | 15.5 | 62.50 | 125 | 4 | 8 | 6 | 9.5 | 7 | 31.7 | 436.6 | 5.7 |

| 1.5 | 1000.00 | 6 | 200 | 17 | 17 | 15.5 | 62.50 | 125 | 8 | 8 | 6 | 9.5 | 7 | 31.7 | 936.6 | 5.7 |

| 2 | 500.00 | 8.5 | 75 | 24 | 24 | 22 | 62.50 | 125 | 4 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 |

| 2 | 1000.0 | 8.5 | 150 | 24 | 24 | 22 | 62.50 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 |

| 3 | 500.00 | 10.3 | 50 | 29 | 29 | 26 | 62.50 | 125 | 4 | 9 | 10 | 15 | 9 | 35.0 | 430.0 | 7.7 |

| 3 | 1000.0 | 10.3 | 100 | 29 | 29 | 26 | 62.50 | 125 | 8 | 9 | 10 | 15 | 9 | 35.0 | 930.0 | 7.7 |

| 4 | 506.67 | 13.8 | 38 | 39 | 39 | 35 | 62.50 | 125 | 4 | 12 | 10 | 15 | 9 | 33.3 | 433.0 | 7.7 |

| 4 | 1000.0 | 13.8 | 75 | 39 | 39 | 35 | 62.50 | 125 | 8 | 12 | 10 | 15 | 9 | 33.3 | 933.4 | 7.7 |

| 5 | 500.00 | 17.4 | 30 | 49 | 39 | 34 | 62.50 | 125 | 4 | 12 | 14 | 20 | 13 | 37.5 | 425.0 | 11.7 |

| 5 | 1000.00 | 17.4 | 60 | 49 | 39 | 34 | 62.50 | 125 | 8 | 12 | 14 | 20 | 13 | 37.5 | 925.0 | 11.7 |

| 6 | 500.00 | 20.9 | 25 | 59 | 49 | 43 | 62.50 | 125 | 4 | 16 | 18 | 26 | 17 | 37.5 | 425.0 | 15.7 |

| 6 | 1000.0 | 20.9 | 50 | 59 | 49 | 43 | 62.50 | 125 | 8 | 16 | 18 | 26 | 17 | 37.5 | 925.0 | 15.7 |

| 8 | 480.00 | 28.0 | 18 | 79 | 79 | 71 | 60.00 | 120 | 4 | 25 | 22 | 33 | 21 | 120.0 | 240.0 | 17.7 |

| 8 | 960.00 | 28.0 | 36 | 79 | 79 | 71 | 60.00 | 120 | 8 | 25 | 22 | 33 | 21 | 120.0 | 720.0 | 17.7 |

Applications

- Machine tools, milling machines, drills, lathes, machine center, cutting machines, carpentry machines, welding machines, stone fabricating machines, etc.

- Lift mechanisms / Guide mechanisms / Steering mechanisms, etc.

- Ideal for working with heavy duty loads and motion.

- Movies

- Related Products

Helical Gear / Cycloid Gear

We remain committed to advancing the field of helical/cycloid gear technology and supporting...

DetailsSpur Gears

Yieh Chen manufactured precision machining of metal gear parts for the aviation and aerospace...

DetailsBevel / Spiral Bevel Gear

Through collaboration with research institutes and our supply chain, we have progressed from...

DetailsWorm / Worm Shaft

We have successfully expanded from solely providing cylindrical gears to becoming experienced...

Details- Files Download

Precision Spur / Helical Gear Rack | Enhance Your Production Line with Yieh Chen Thread Rolling Machines: Precision Engineering for Optimal Performance

Yieh Chen Machinery Co., Ltd. is a leader in the global manufacturing of high-precision gears and transmission components. This ISO9001 & AS9100 certified company, a member of the Six Star Group, offers a comprehensive range of products including Precision Spur / Helical Gear Rack, spur gears, helical gears, gear racks, worms, worm shafts, and various specialized machines. Yieh Chen's commitment to quality and innovation is evident in their use of advanced technologies and adherence to stringent international standards, making their products essential for diverse and demanding applications in industries such as aerospace and agriculture.

Yieh Chen Machinery Co., Ltd is the affiliate of Six Star Group. Six Star was founded in 1975 by Six brothers and devoted to the manufacturing of precision gear products. Yieh Chen Machinery was established in 1984 into the market of machinery industry and is dedicated to produce Thread rolling machine and Spline rolling machine with high quality and durable lifetime. Yieh Chen Machinery Co., Ltd. is a gear manufacturer of gear for air screw compresser, cnc lathes, machining center, printing machines and more. Also, we providing quality thread rolling machine, spline rolling machine, multi forming machine.

Yieh Chen has been offering customers durable machine tools for manufacturing, both with advanced technology and 40 years of experience, Yieh Chen ensures that each customer's requirements are met.